Introduction

Hello all!

Let’s start with a question: what do you know about sanding? You know, removing nubs and stuff. Something you wouldn’t associate with sanding is, well, sponges. And that is what we are here to talk about today: sanding sponges!

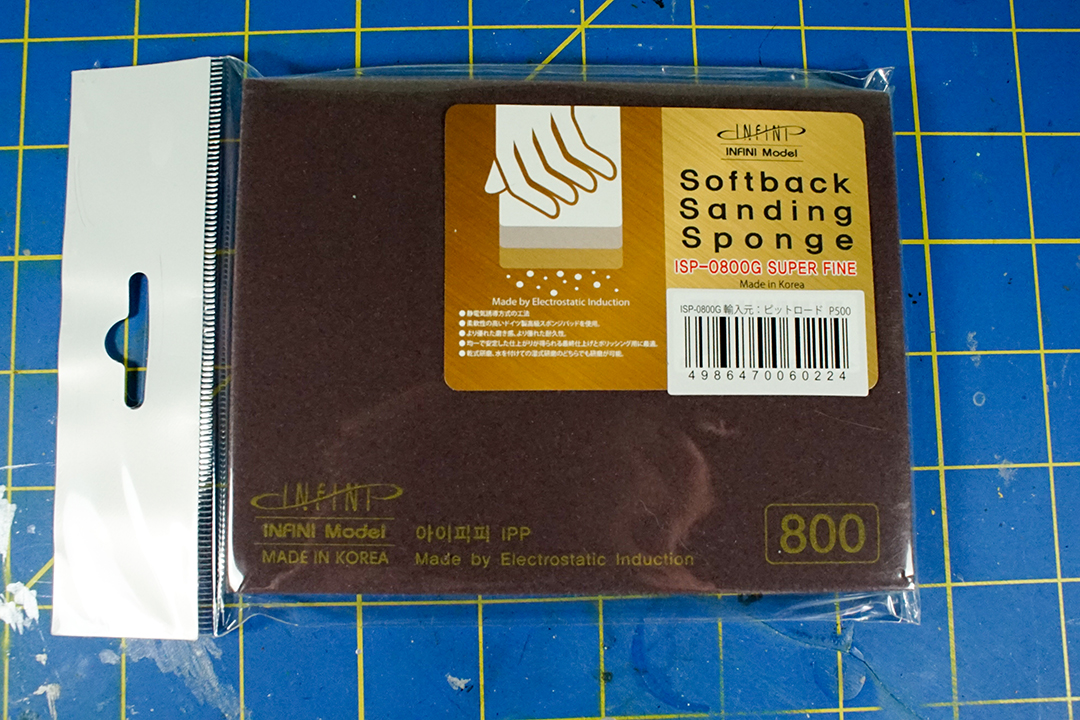

We will be looking at the Softback Sanding Sponge Stick #220 Coarse and the Softback Sanding Sponge #800 Super Fine.

What are sanding sponges?

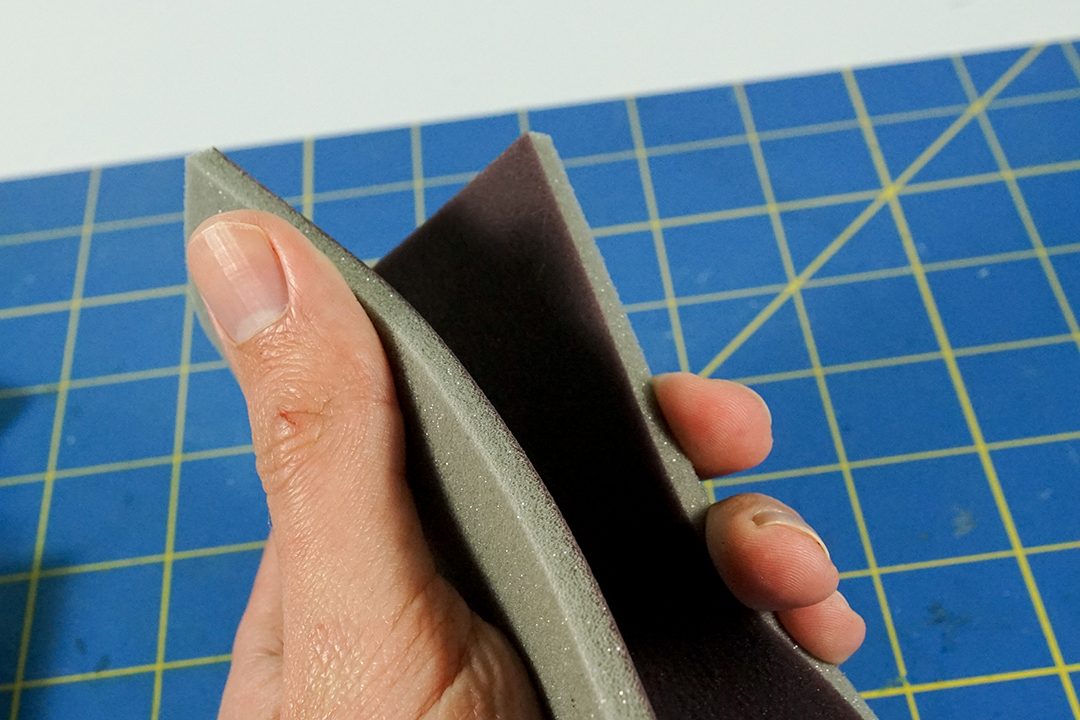

So what are sanding sponges? How are they different from, say, sanding sticks or files? It’s actually quite interesting. So, first of all, as the name suggests, they are used for sanding. But what makes these sanding sponges unique is the ability to mold into the part.

Think of it as one of those memory foam mattresses, but it is for the part you are sanding.

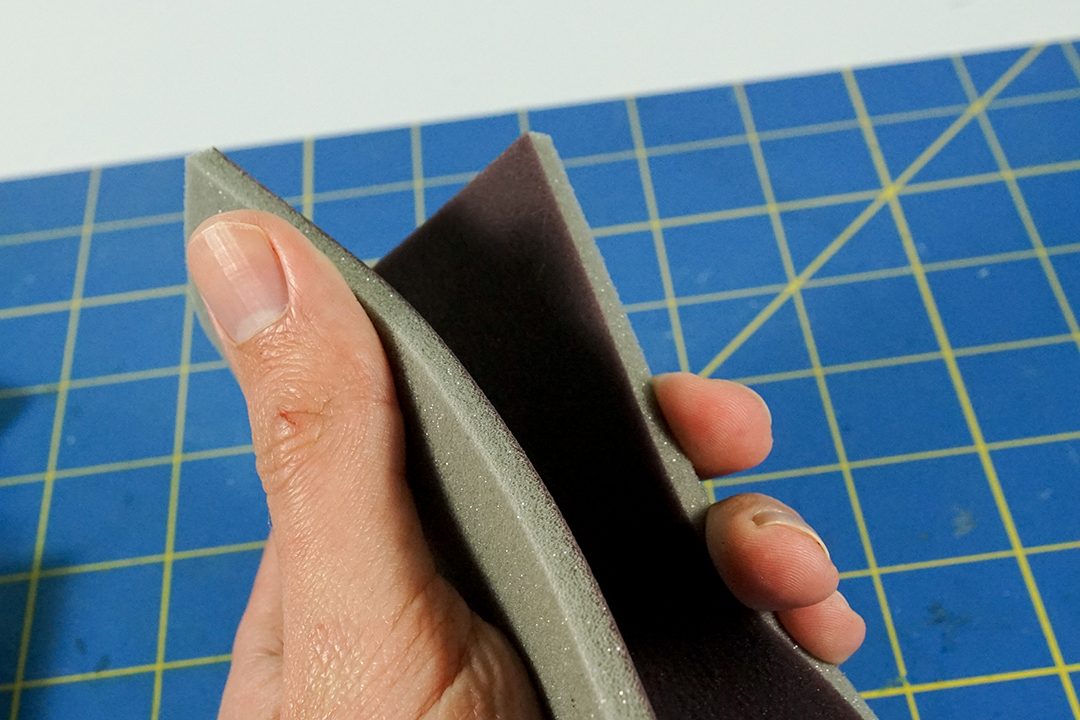

Both the stick and the sponge are very flexible.

This is to help with parts that have more of a curve to them. Unlike traditional sanding sticks/ files that are straight edges and can’t really bend or may take off more than you want when sanding down nubs.

All about grits

Now how do you know what type of sanding sponge you need? Just like nearly all sanding equipment, the sanding sponges fall into the same grit categories.

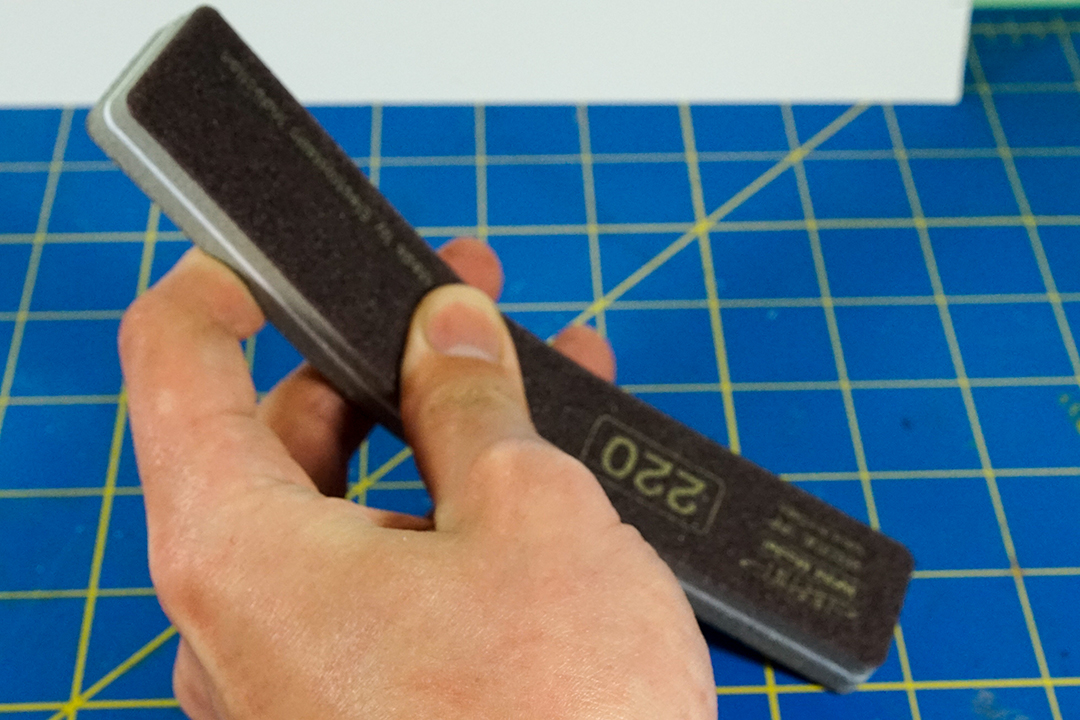

For instance, the Sanding Sponge Stick I’ve got has a grit of 220, which means it is very fine. And to quote grainger.com: “the least fine of the micro-abrasives.”

However, it is also coarse, which means that it is rather rough. As noted by the COARSE indication on the label.

How to use it

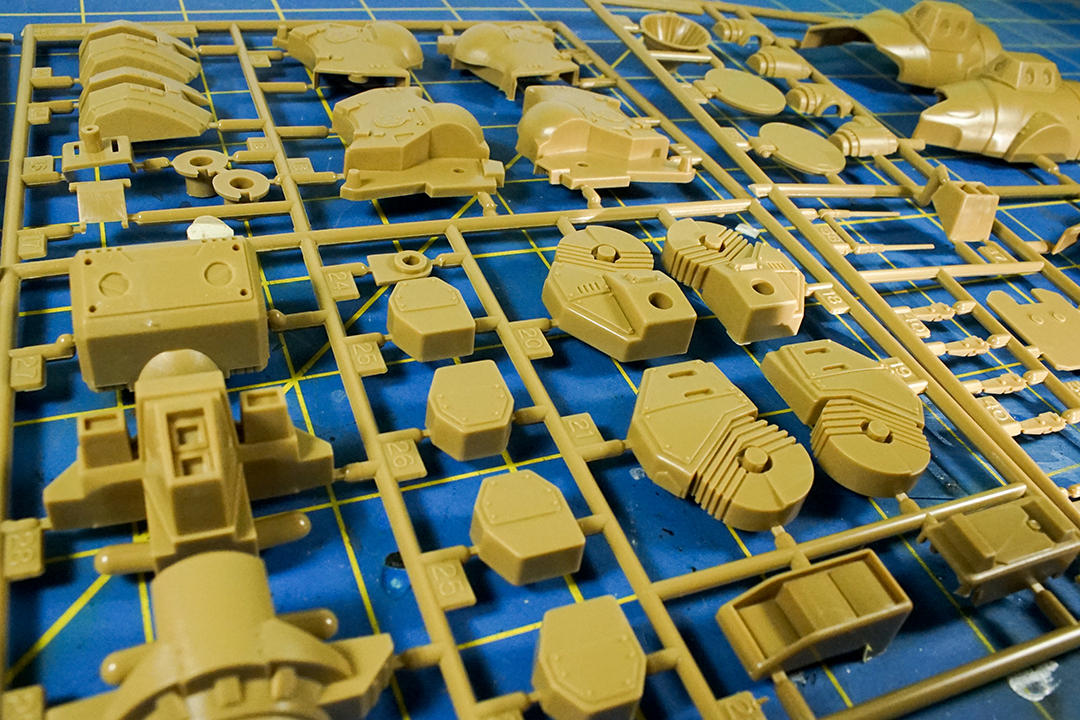

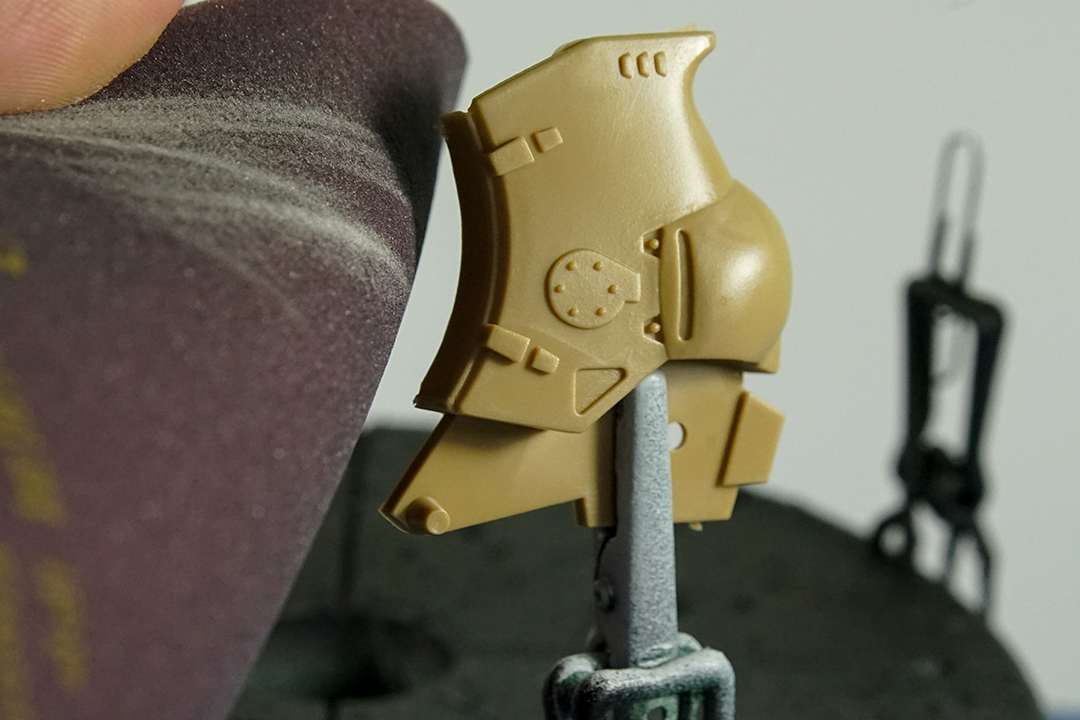

As mentioned above, sanding sponges are great for kits with curves. We are using the 1/100 Missile Phalanx from the anime series Super Dimensional Fortress Macross to help us show off how effective this is.

This kit is relatively unique for its abundance of curvature points.

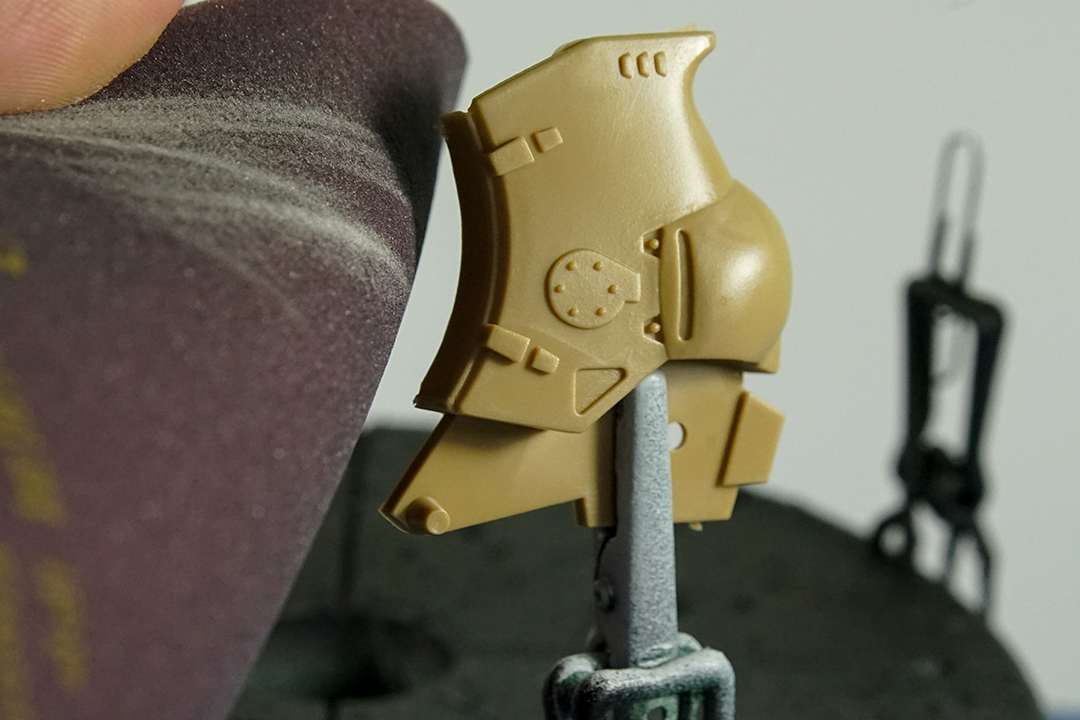

Basically, as stated above, you just take the sanding sponge you need and just start sanding. Because of the soft material the sponge is made of, it easily takes the shape of the part you are sanding.

(I highly recommend you sand properly by holding the parts in your hands and not on a stand like this; this is for review only, but if you can actually sand like this, then wow! Pat yourself on the back.)

Comparison

As you may have noticed, we have two types of sanding sponges: the 220 coarse and the 800 ultra-fine. And I bet you’re wondering, so what is the difference because these are honestly two different products. Let’s start with:

Sanding Sponge Stick #220

As stated above, this Sanding Sponge Stick has a grit of 220, which is the least fine of the micro-abrasives. It’s also very coarse. Basically, it can make short work of those nubs but can be very harsh on the part.

The sponge itself is very ridged like a traditional sanding stick.

Yet, it can still bend when needed.

As well because of the spongy material, it can shape around the part.

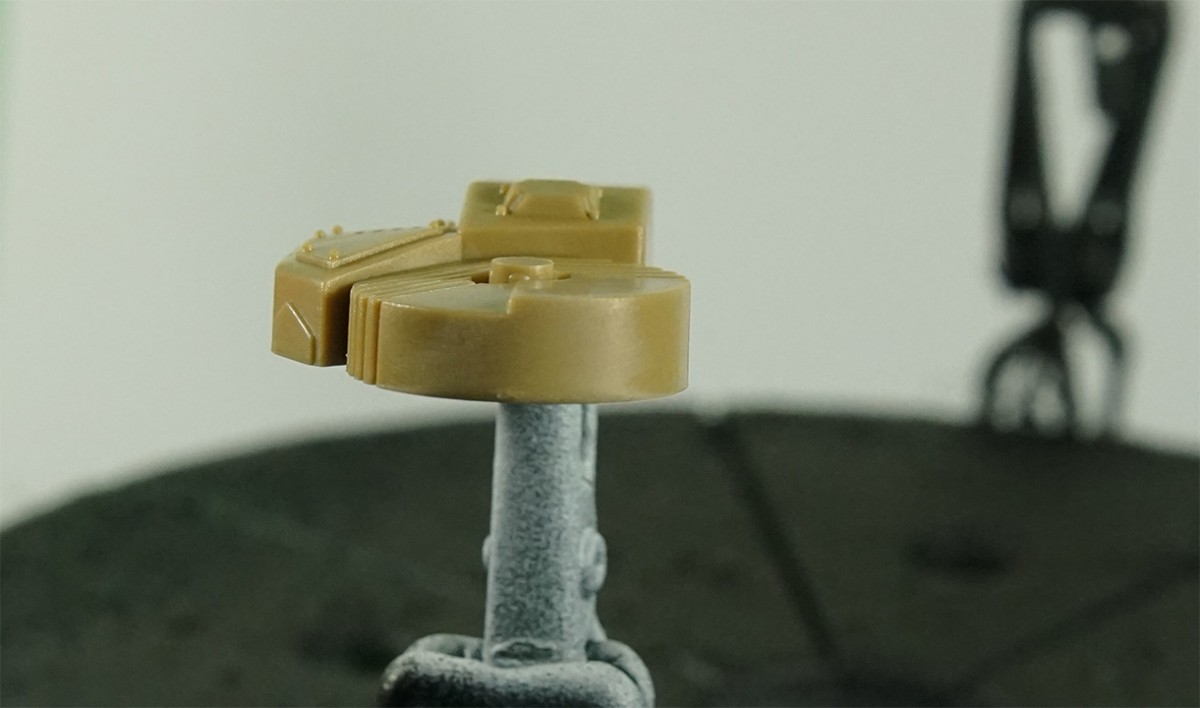

Here are the results of the Sanding Sponge Stick.

Before:

After:

Sanding Sponge Super Fine #800

Unlike the sanding stick, this Super Fine sanding sponge has a grit of 800, which means it is… well, super fine. Basically, to quote grainger.com again, it “slightly wipes away patches/small inconsistencies but not strong enough for removal.”

But that is not the only difference; unlike the stick, this one feels more like a sponge, similar to the green ones you use to clean dishes.

The material is very soft and highly flexible, able to take nearly any shape.

Honestly, because of its ability to bend like this, I say it is perfect for larger parts with many nub marks, like this leg part on the Phalanx.

Now for the comparison.

Before:

After:

While it didn’t do as much abrasion to the part, the nub is still kind of there.

And for this amount of sanding, it did leave the sponge with some battle damage.

Conclusion

As someone who uses files and worries about sanding too far down or losing a curve or roundness to a part — after all, we all know how curvy a lot of these model kits can be — these sanding sponges are a game changer, and I wish I’d tried them before.

I guess the idea of sanding sponges was a concept that kind of confused me. When I think sponge, I think water. So it just didn’t make sense to me in my head.

Would I recommend them? Yes!

Would I recommend these exact two? Well, that is for you to decide, as in what grit and texture you need. Honestly, I may end up sanding with the 200 grit and then use the 800 for clean up, and keep using my files in addition to these two.

I hope this little blurb on sanding sponges was able to help you understand more of how this amazing product works.

Thank you for stopping by,

– Zeroconvoy